Extension Cord Safety

Date Posted: 02/16/2024

Flexible extension cords, powering tools, lighting, and equipment are everywhere on construction sites. These cords are often loose and uncovered, exposing them to opportunities for damage. They can cause tripping hazards. They also can be damaged easily and can create electrical hazards to personnel on the site. An electric shock can result in an electrical burn or even heart failure and death. A shock that is strong enough to throw you away from the electrical source can also result in other physical injuries.

Note: Extension cords (flexible cords) are typically used to connect electrical equipment to a power source. The terms flexible cords, extension cords, cables, and electrical cords all refer to a type of flexible cord.

Considerations that Affect Extension Cord Safety

According to the Occupational Safety and Health Administration (OSHA), because extension cords are “flexible and unsecured, they are susceptible to damage.” Below are some considerations that OSHA presents to increase extension cord safety on construction sites.

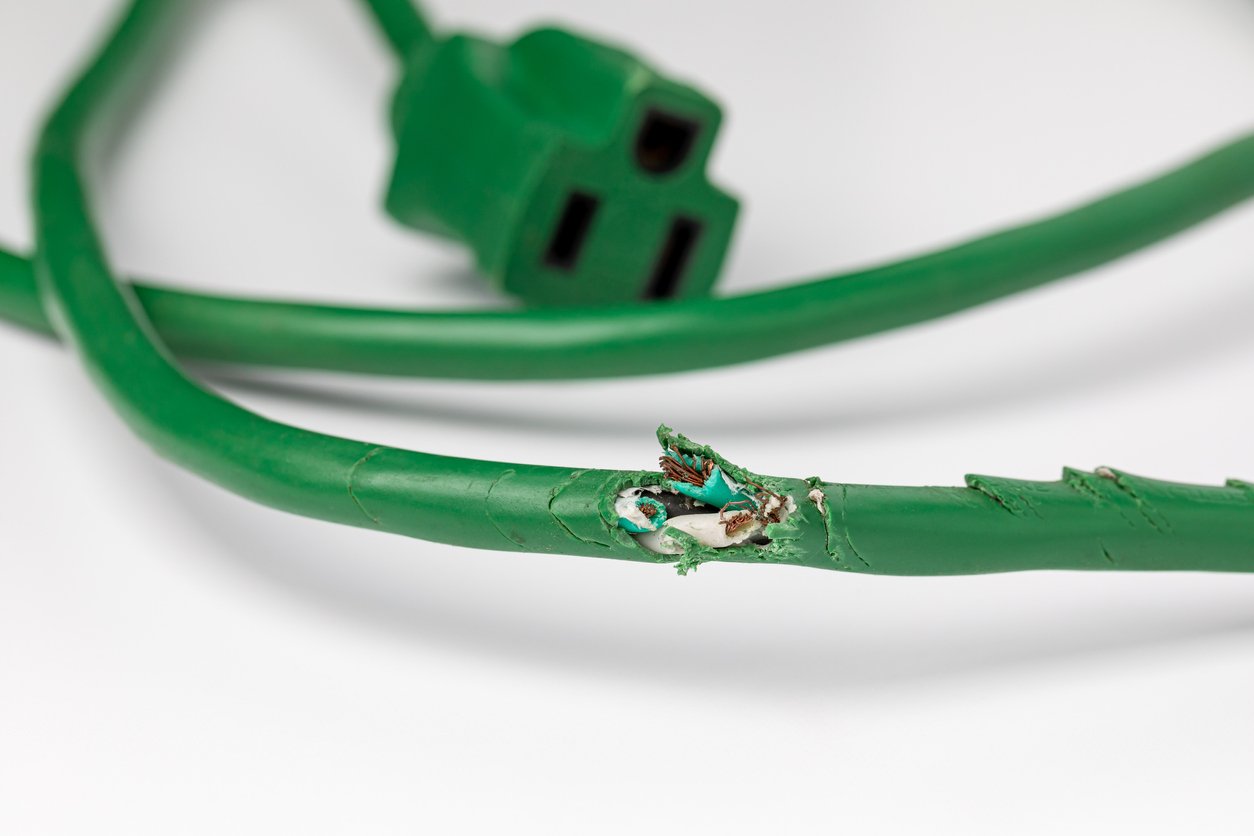

Cord Damage

An extension cord may be damaged by a door or window edges, by staples and fastenings, by abrasion from adjacent materials, or simply by aging. If the electrical conductors become exposed, there is a danger of shocks, burns, or fire.

Grounding

Extension cords must be 3-wire type so they may be grounded and permit the grounding of any tools or equipment connected to them.

Use in Wet Conditions

When a cord connector is wet, electric current can leak to the equipment grounding conductor and to humans who pick up that connector if they provide a path to the ground. Electrical current leakage can occur not just on the face of the connector but at any wetted portion. Limit exposure of connectors and tools to excessive moisture by using watertight or sealable connectors.

Strain Relief:

To reduce hazards, flexible cords must connect to devices and fittings to prevent tension at joints and terminal screws. Flexible cords are stranded for flexibility, so allowing a cord to strain can cause the strands of one conductor to loosen from under terminal screws and touch another conductor.

Durability: Flexible cords must be rated for hard or extra-hard usage. These ratings are derived from the National Electrical Code (NEC) and must be indelibly marked approximately every foot along the length of the cord.

What Do the Markings on An Extension Cord Mean?

It is essential to use the right extension cord for the right environment. Extension cords have markings printed on the cords themselves, which have significance. The codes come from the National Electric Code (NEC) and mean the following:

| Marking | Description |

|---|---|

| S | Hard Service Flexible Cord |

| SJ | Junior Hard Service Flexible Cord |

| E | Thermoplastic Elastomer Insulation |

| T | Thermoplastic Insulation |

| O | The jacket is Oil Resistant |

| OO | The jacket and conductors are Oil Resistant |

| R | Thermoplastic Rubber Insulation |

| X | Cross-linked Synthetic Polymer Insulation |

| HH | High Temperature |

| W | Moisture Resistant |

| N | Nylon Jacket |

Extension Cord Dos and Don’ts

Do:

Visually inspect cords before use.

Remove from service any cords that have damage.

Inspect extension cords before each use.

Discard cords that are cut, frayed, damaged, missing ground plugs or exposed wires, or wrapped with any tape (duct tape, electrical tape, etc.).

Use extension cords only for temporary power needs.

Use cords with three prongs.

Use ground fault circuit interrupter (GFCI) protectors.

Disconnect cords at the plug rather than by pulling on the cord.

Prevent cord damage by putting cable protectors over any cord that crosses a walkway.

To prevent pinching, coil cords properly and not by wrapping them around your arm.

Don’t:

Run cords through doorways, ceilings, walls, windows, or any other opening.

Do not conceal cords in walls or floors.

Run cords around sharp or abrasive corners.

Use extension cords in place of permanent wiring.

Put carpeting, cardboard, or anything other than a cable protector over an extension cord.

Connect two extension cords.

Use cords longer than 100 feet.

Remove the grounding prong on the plug.

Wrap duct tape or electrical tape on a damaged cord.

Use staples or nails to secure an extension cord.

Roll carts or vehicles over unprotected cords.

Resources

WAC 296-155-449 - Wiring Methods, Components, and Equipment for General Use

Electrical - Flexible Cords | Occupational Safety and Health Administration (osha.gov)

1926.416 - General requirements. | Occupational Safety and Health Administration (osha.gov)